Precision Machining Operations

Precision Machining Operations

Program Overview

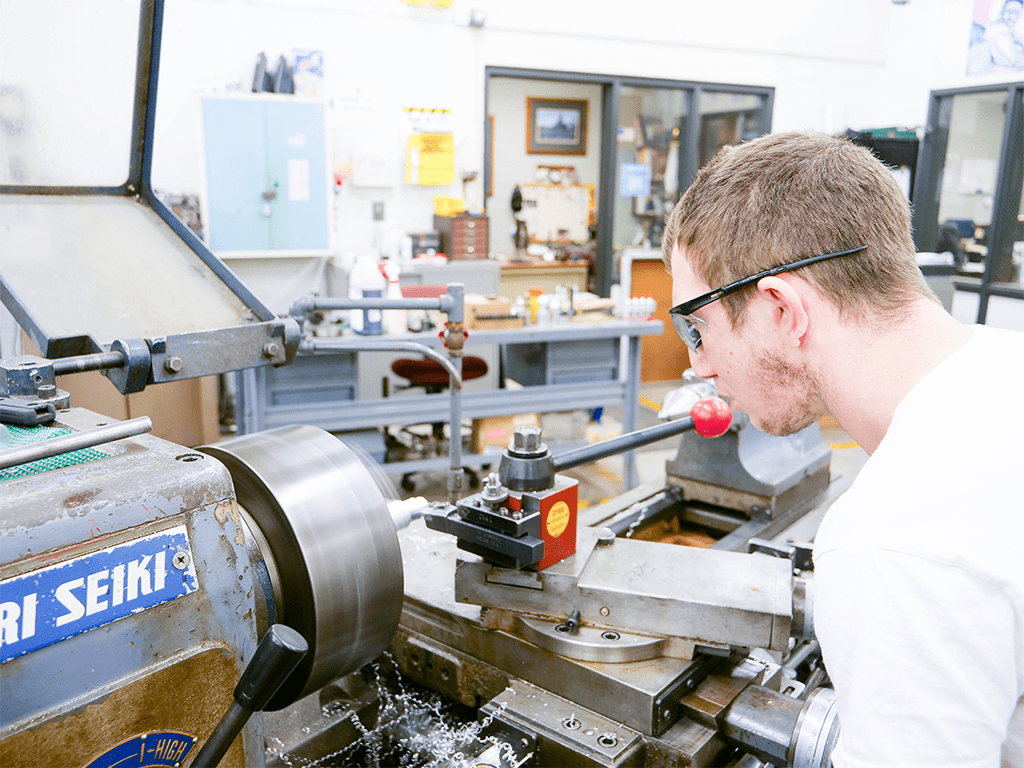

Precision machinists make the things that make today’s technology work! The work is challenging, satisfying and technical. In Tri County Tech’s Precision Machining Operations courses, you will learn the proper techniques to become a certified, career-ready machinist. According the last US Census, precision machining is a $9 billion industry and is expected to continue to grow at a 6% rate until 2030.

★★★★★

Students taking Precision Machining classes can expect:

- HYBRID LEARNING – reading material and some coursework will be online at home. Testing and shop work will be scheduled in-person classes.

- FAST-PACED – our flex program is condensed learning in an accelerated environment.

Application Deadline

- Applications are due ONE WEEK before the course starts.

To start or continue your application, visit here.

Course Schedule

Basic Machine Operation

This is an introductory course – no experience is necessary.

This course provides an introduction to the fundamental principles and practices of manual machine operations in the field of precision machining. Students will gain hands-on experience with essential machining tools and equipment, including lathes, milling machines, saws, and grinders as well as hand tools and measuring devices. Safety procedures, blueprint reading, machine setup, tool selection, measurement techniques, and basic maintenance are key topics. Through practical exercises and projects, students will develop the skills to perform accurate and efficient machining tasks, laying the foundation for advanced studies in precision manufacturing and engineering. This course is ideal for beginners seeking to enter the machining industry or enhance their technical abilities.

| Program Dates | Program Days | Program Times |

| TBD | TBD | TBD |

| Program Length | Program Instructor | |

| 88 Total Hours | James Cowart | |

| In District Cost | Out of District Cost | Out of State Cost |

| $700 | $800 | $1,000 |

CNC Mill and Lathe

This course provides a comprehensive introduction to CNC (Computer Numerical Control) mill and lathe operations—essential tools in modern precision machining. Students will learn to program, set up, and operate both CNC milling machines and CNC lathes to produce parts with intricate geometries and exact specifications. The curriculum includes G-code programming, tooling and material selection, machine setup, calibration, and troubleshooting techniques. Emphasis is placed on safety procedures, precision measurement, workflow efficiency, and process optimization. Through a mix of theoretical instruction and hands-on projects, students will gain the technical skills and practical experience needed to excel in the advanced manufacturing industry.

*Basic Machining or CNC Skills must be completed as a prerequisite to CNC Mill and Lathe.

| Program Dates | Program Days | Program Times |

| 07.08.2025 – 11.06.2025 | Tuesday, Thursday | 6:00pm – 9:00pm |

| Program Length | Program Instructor | |

| 105 Total Hours | James Cowart | |

| In District Cost | Out of District Cost | Out of State Cost |

| $900 | $1,100 | $1,300 |

Advanced CNC Machining and Manufacturing

This advanced course builds upon foundational knowledge from Basic Machine Operation, CNC Mill, and CNC Lathe courses, focusing on the integration of advanced machining techniques and manufacturing processes. Students will deepen their expertise in CNC programming, multi-axis machining, and complex part production using both mills and lathes. The curriculum emphasizes precision, efficiency, and quality control through the use of CAD/CAM software, automated toolpath generation, and advanced setup procedures. Students will engage in real-world projects that simulate industry standards, incorporating lean manufacturing principles, inspection protocols, and workflow optimization. This course prepares students for high-level roles in precision manufacturing, CNC programming, and process engineering, equipping them with the skills required for today’s dynamic and technologically driven manufacturing environments.

*CNC Mill and Lathe must be completed as a prerequisite.

| Program Dates | Program Days | Program Times |

| 11.11.2025 – 03.12.2026 | Tuesday, Thursday | 6:00pm – 9:00pm |

| Program Length | Program Instructor | |

| 90 Total Hours | James Cowart | |

| In District Cost | Out of District Cost | Out of State Cost |

| $1,000 | $1,100 | $1,300 |

Career Opportunities

| Drill Press Operator |

| Manual Lathe Operator |

| Manual Mill Operator |

| CNC Lathe Operator |

| CNC Mill Operator |

| CNC Programmer |

| Inspector |

Career Data

| Our Placement Rate | 89% |

| Median Hourly Earnings* | $24 |

| Completion/Retention Rate | 100% |

| *Information provided by the U.S. Bureau of Labor Statistics Data. |

Certifications

Financial Assistance

Financial assistance is available through the Tri County Tech Foundation for our Full-Time and many of our Flex programs. After you are accepted into a program, you will receive a financial assistance application. The form must be filled out and turned in with the most recent two months of pay stubs for every working member of your household.

Our main goal for financial assistance at Tri County Tech is to assist financially disadvantaged students who would be unable to get the education they deserve. Assistance consists of grants, scholarships, and employment. An individual might participate in one or more resources, depending upon eligibility and need.

We do not accept funds from FAFSA or PELL.

If you have any questions, please feel free to reach out to us!

Questions?

Contact Us!

Our Student Services team assists potential students in finding the right program, financial assistance, and also works with local businesses in Bartlesville to help students apply to Tri County Tech. If you have any questions, contact us today or visit our Student Services team at our main Bartlesville campus.